When I stumbled upon a Handshake listing for Bryn Mawr’s Makerspace Spring Intensive over winter break, I felt a jolt of excitement but hesitated to enroll. I’d always had lofty dreams of satisfying my creative impulses by printing vinyl stickers, risograph zines, and more, but thought learning to do so was much too design-heavy—and technologically advanced—for me to take on during a busy semester. Fortunately, I was able to push past my concerns, and am so glad I did. Even though I’ve just begun working on projects, I'm grateful to have access to such a unique resource on campus.

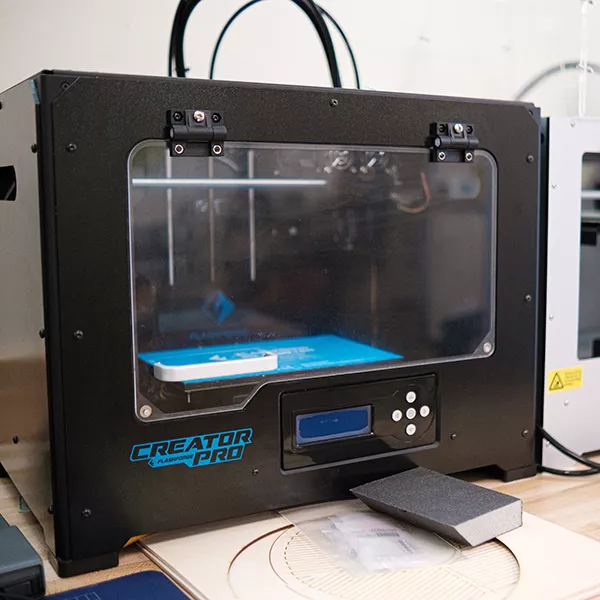

For those who are unfamiliar, the Bryn Mawr Makerspace is a creative area in Park 157 that houses tools for 3D scanning and printing, laser cutting and etching, physical computing, sewing, textile arts, basic carpentry, woodworking, sticker printing, and risograph printing. The space is operated by Makerspace Coordinator Bronwen Densmore, who is also the facilitator of our intensive.

"We're here so that students have an opportunity to use emerging technologies, build skills in traditional making methods, and explore the ways the work they're doing in their courses may be furthered by creative making projects—essentially, testing their ideas out in three dimensions," says Bronwen of the services the Makerspace offers to the Bryn Mawr community.

For our first project, intensive participants were tasked with creating a sticker design. To help guide us through the brainstorming process and encourage the spirit of collaborative learning, we were asked to consider how our artistic choices are influenced by our choice of tool, how to most efficiently use materials, and to ruminate on what forms of graphic design work best within a sticker format.

It didn’t take me very long to decide that I wanted to print sticker prototypes of the logo for Haverstand, a recently launched Bi-Co farmstand with locally sourced fish and produce that I create marketing materials for. However, Bronwyn’s questions helped me view my project from a more technical perspective. I discovered that tracing circular cut lines in Adobe Illustrator—especially as a beginner—proved to be challenging. Maneuvering the circular logos so that I got the most of the vinyl template provided to me also required some trial and error.

Luckily, when I showed up at my in-person printing appointment on a Saturday afternoon, Bronwen was there to greet me and coach me through the editing process. I sent her a copy of my project and I followed along as she ran through the steps that were necessary to prepare my design for the printer.

The printing itself only took about 5 minutes, and I had a great time getting to know Bronwen—and excitedly aligning my face with the glass viewer—as the printer carefully sprayed ink onto the white vinyl canvas.

I'm excited to give out stickers to my Haverstand team members this week and intend on printing more for customers as soon as I can. I’m also eager to continue making progress with the spectacular tools in the Makerspace—and learn to be a thoughtful, sustainable, mission-minded maker who can carry her new design skills beyond Bryn Mawr.